INTRODUCTION

In medicine, radiological images are utilized as an aid to diagnosis, treatments and also in images-guided procedures. For such purposes, the image must meet a certain level of quality, so as to minimize errors of interpretation and identification of structures, thus allowing an accurate diagnosis with low radiation levels. Otherwise a low quality image causes the repetition of imaging studies and, consequently, the duplication of radiation dose in the same patient, besides additional costs to the radiology service(1).

The benefits from an appropriate radiological image can be attained by means of the implementation of equipment quality assurance programs in radiodiagnosis centers. According to the World Health Organization, quality assurance in diagnostic radiology is defined as “an organized effort by the service management towards assuring that images are acquired with enough quality to allow an appropriate diagnosis with the lowest radiation dose to the patient”(2).

In Brazil, the development of techniques and devices for quality control in radiology started at the Physics Department in the Ribeirão Preto Campus of Universidade de São Paulo since the mid-1970s, by Professor Thomaz Guilardi Neto, assisted by Professor John Cameron. Professionals were educated and prepared to perform evaluation techniques, and have implemented the first quality programs of throughout São Paulo and other Brazilian states.

With the publication of Resolution SS 625/94, of December 14, 1994, the implementation of quality control programs became mandatory in the state of São Paulo(3). Following the successful implementation of the programs in the state of São Paulo, the Ministry of Health issued the Order (Portaria) MS/SVS 453, on June 1st, 1998(1).

Order 453 establishes the need to implement a quality assurance program (QAP) in radiology center(4,5). As a result, it establishes that every diagnostic X-ray equipment must be subject to periodical evaluation of their performance by means of several constancy tests, such as, for example: measurement of the representative dose value delivered to the patients submitted to radiography at the center; testing of the accuracy of X-ray tubes voltage indicator (kVp); evaluation of the accuracy of exposure time, as applicable; testing of the X-ray beam alignment; X-ray tube performance test; testing of the air kerma rate linearity as a function of the mAs, testing of automated exposure system reproducibility; measurement of the focal point size; evaluation of collimation system accuracy; and grid alignment test(6).

For the present study, Agência Estadual de Vigilância Sanitária da Paraíba (Agevisa-PB) (Paraíba State Department of Health Surveillance) provided the research instruments required for the testing of collimation system accuracy and X-ray beam alignment. Because of their simplicity and facility, the tests allowed a critical evaluation of the apparatuses with respect to collimation of radiation in the patients’ areas of interest and the distortion of the radiographic image, allowing the minimization of risks resulting from radiation exposure, minimization of the dose delivered both to patients and workers, costs optimization, reduction of films rejection and wear on the equipment, besides a better quality in radiographic image standards, thus contributing for accurate diagnoses(7).

The collimation system accuracy testing is aimed at evaluating the congruence between the light and radiation fields limited by the equipment collimator, thus avoiding X-rays reaching unintended areas of the patient’s body during the radiological examination. On the other hand, the testing of X-ray beam alignment is aimed at evaluating the perpendicularity between the center of the light field and the plane of the image reception system, thus avoiding the radiographic image distortion(8).

The present study was aimed at evaluating the light and radiation fields congruence and radiation beam alignment in medical X-ray equipment in Paraíba state, private and philanthropic radiology centers by means of two quality control tests (QCT) as follows: testing of collimation system accuracy and X-ray beam alignment performed in the years of 2008 and 2009 by the technical team of the Agevisa-PB ionizing radiations sector.

MATERIALS AND METHODS

The present study is of the observational, descriptive and comparative type, as it informs, in quantitative terms, on the distribution of an event in the population, and compares the testing results in the same apparatuses in different years(9).

The data recording was performed by a single investigator and the visits were carried out during health surveillance inspections following the normal operational routine of the radiological centers. Because of ethical confidentiality considerations, the hospitals and radiological centers visited during the present study were not identified. So, inspected institutions are only classified according to the service network they belong to, as public, private and philanthropic.

In 2008, 121 X-ray apparatuses belonging to 87 radiology services in the state of Paraiba underwent QCT. Among them, 42.14% (

n = 51) belonged to the public health system, 55.37% (

n = 67), to private clinics, and 2.47% (

n = 3), to philanthropic centers.

In 2009, 117 apparatuses were submitted to the same tests in the Paraíba state, 38.46% (

n = 45) of them in the public health network, 56.41% (

n = 66), in the private network, and 5.12% (

n = 6) in the philanthropic network.

Of this universe, 71.07 % (

n = 86) of the apparatuses were selected for comparison, since they had been evaluated both in the years of 2008 and 2009.

The tests performed in the present study were the following: X-ray beam alignment collimation system accuracy, according to the Brazilian protocols for QCTs(6,10) and a medical radiodiagnosis handbook(11). The following instruments were utilized for each evaluation: devices for field size testing (plate with radiopaque markings with two orthogonal axes in scales of 0.5 cm and two concentric circles) and, for the X-ray beam alignment (a plastic cylinder with 0.8 mm-diameter steel spheres placed at lower and upper bases at a distance of 15 cm), a (preferably 24 × 30) cassette loaded with film, a measuring tape and a bubble level(8,12).

For the evaluation of the collimation system accuracy, a 24 × 30 loaded cassette was placed on the table’s surface, and over such cassette the device for field size measurement, in such a way that such device was perpendicular to the X-ray beam. After adjustment of the focus-film distance to 1m, the adjustment of the edges of the light field was made so that it matched the rectangular outline of the plate, through the X-ray equipment collimator. For the X-ray beam alignment, the beam alignment device was placed at the center of the collimator test device. Subsequently, an exposure utilizing approximately 40 kVp and 3 mAs(11) was made.

After the evaluation of the tests results, in those cases in which the X-ray apparatuses were not in compliance with the standards, the institutions to which they belonged were notified and deadlines were established for corrective maintenance, after which the inspection team would perform new tests in the same apparatuses to check on the adjustments made.

In the present study, in order to evaluate the results, the X-ray apparatuses were classified according to their models, into fixed equipment and portable equipment. The portable apparatuses that were being utilized as fixed equipment were included in the present study as fixed equipment.

RESULTS

The data obtained by the present study developed in the years of 2008 and 2009 are categorical, with no margin for error. Among the apparatuses existing in the Paraíba state, a significant sample (71.07%;

n = 86) was analyzed in both years.

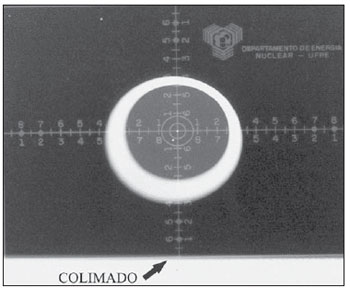

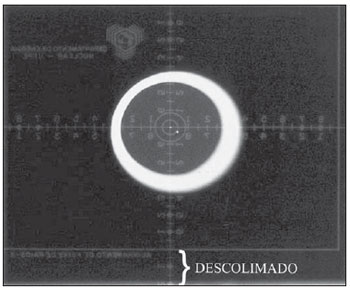

The congruence between the light and radiation fields was evaluated for analysis and interpretation of the images of the collimator test. The largest distance between the borders of the light field and those of the radiation field was measured. The greater the congruence between the light and the radiation fields, the better is the alignment. The difference between the borders of the radiation field and the borders of the light field must not be greater than 2% of the focus-film distance that is ± 2 cm away from the line corresponding to the device’s rectangle(9,11). The images generated on this test are represented on Figures 1 and 2.

Figure 1. Collimation system accuracy test. Image demonstrating compliant fields congruence.

Figure 2. Collimation system accuracy test. Image demonstrating non compliant fields congruence.

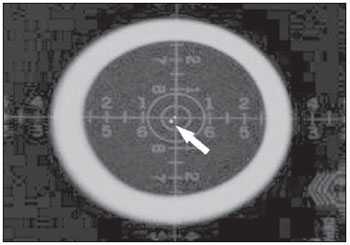

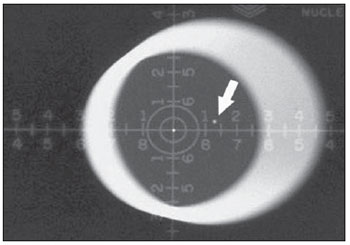

As regards the analysis and interpretation of the X-ray beam alignment test, the location of the image of the sphere on the top of the cylinder was verified. If the image of the upper sphere was within the first circle, the inclination corresponded to < 1.5º. In those cases where the image of the upper sphere was located between the first and the second circles, the inclination was < 3º(11). Whenever the image of the upper sphere intercepted the second circle, the perpendicularity of the central ray must be corrected(8). Figures 3 and 4 represent the images of the X-ray beam central axis alignment test.

Figure 3. Central ray perpendicularity test. Image demonstrating the compliant incidence of the X-ray beam central ray.

Figure 4. Central ray perpendicularity test. Image demonstrating the non compliant incidence of the X-ray beam central ray.

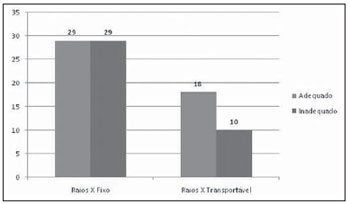

In the present study, in the year of 2008, QCTs were performed in 92 fixed X-ray apparatuses and in 29 portable apparatuses, in different centers belonging to the public health network, private network and philanthropic network.

Among the 121 tested apparatuses, 32.23% (

n = 39) presented problems regarding the collimation system accuracy and/or alignment of the X-ray beam central ray, most of those 39 apparatuses (

n = 22) belonging to private centers. Among the tested apparatuses, 23.96% (

n = 29) were classified as fixed X-ray apparatuses with problems, while 8.26% (

n = 10) were portable apparatuses that were not compliant with the quality assurance standards.

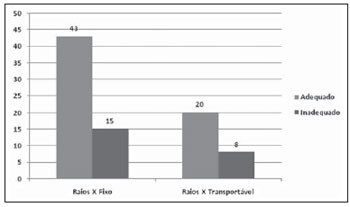

In 2009, 117 apparatuses (89 fixed and 28 portable) were tested in the Paraíba state. Among those apparatuses, 19.65% (

n = 23) presented problems in the collimation system accuracy and/or X-ray beam alignment, most of them (

n = 13) belonging to private clinics. As regards the classification of the apparatuses, among all the apparatuses monitored in 2009, 12.82% (

n = 15) were classified as fixed apparatuses with problems, and 6.83% (

n = 8), as portable, non compliant apparatuses.

In the present study, 71.07% (

n = 86) of the apparatuses tested in 2008 were tested again in 2009, with improvement in QCT results of 18.6% (

n = 16) from one year to another (Figures 5 and 6). The other apparatuses tested in both years obtained the same satisfactory results on the collimation system accuracy and central ray perpendicularity tests, with no change in results.

Figure 5. Chart demonstrating the classification of the X-ray apparatuses into fixed and portable apparatuses, according to the results of the quality control tests performed in the Paraíba state in 2008.

Figure 6. Chart demonstrating the classification of the X-ray apparatuses into fixed and portable apparatuses, according to the results of the quality control tests performed in the Paraíba state in 2009.

In the collimation system accuracy tests performed in 2008 and 2009, results improvement was observed in 12.79% (

n = 11) of the apparatuses with fields congruence in conformity with the standards (Table 1). Improvement was also observed in X-ray beam central ray perpendicularity test, in 5.82% (

n = 5) of the apparatuses tested in both years (Table 2).

DISCUSSION

In the present study, it was observed that in all the visits, no institution had a QAP in radiodiagnosis, contravening the Order 453/98 of the Ministry of Health which recommends the periodical testing in all the diagnostic X-ray apparatuses with the purpose of maintaining such equipment in appropriate operational conditions. The collimation system accuracy test and X-ray beam alignment test recommended by the Order 453/98 must be performed every six months and annually, respectively. In the present study, the periodicity of both tests was annual, following the annual routine of health surveillance inspections at medical X-ray centers. Additionally, the lack of such a program contributes to the image quality deterioration, with the consequential increase in wasting of films and repetition of imaging studies, thus increasing the radiation exposure for both patients and workers(4,5).

Currently, difficulties regarding the awareness of the regulating agencies on the importance of enforcing the implementation of such programs in the institutions in the Paraíba state are still observed. Additionally, there is a lack of qualified professionals for such programs, and scarcity of qualified and experienced technicians for equipment maintenance once the problems are detected. Not only training in radioprotection for all individuals involved in the operation of radiation emitting equipment is necessary, but it also necessary to assure a perfect operation of such equipment.

The collimation system accuracy tests performed in 2008 demonstrated that 22.1% (

n = 19) of the evaluated apparatuses were non compliant with the light and radiation fields congruence tests (Table 1), with results similar to the ones reported by Medeiros & Alves(12) (17%) and lower than those observed by Silva et al.(13) (30%) and Carrizales & Cozman(14) (41%). As regards the X-ray beam central ray alignment, the results observed in the present study (11.63%;

n = 10) were very low as compared with the results observed by Carrizales & Cozman(14) (53%), in the cases where the radiology centers did not follow a QAP.

As regards the QCTs performed in 2009, the prevalence of non compliant apparatuses in the light and radiation fields congruence tests corresponded to 9.31% (

n = 8) (Table 1), a percentage higher than the one reported by Bacelar et al.(15) (5%) and lower than the one observed by Gori et al.(16) (13%). As regards the X-ray beam central ray alignment, a difference was observed in the number of non compliant apparatuses in 2009 (5.82%;

n = 5) in comparison with the previous year, a percentage considerably lower than the one reported by Silva et al.(13) (17,7%).

CONCLUSIONS

By testing the light and radiation fields congruence and the X-ray beam central ray perpendicularity in apparatuses at Paraíba state radiology centers, it was possible to observe that the non conformities observed were quite significant in the first year, demonstrating the importance of implementing quality assurance programs in radiology centers for prevention and maintenance of the X-ray apparatuses. Adjustments in non compliant apparatuses were only performed after inspection and notification on the non compliance by the inspecting agency (Agevisa-PB), as none of the radiology centers in the Paraíba state had a quality assurance program.

The QCTs performed in the first year of the present study (2008) revealed a high index of non conformities (45.34%), that was significantly reduced in the following year (26.74%), with 18.60% (

n = 16) of the apparatuses tested in 2008 improving their performance in 2009. The remaining apparatuses tested in both years obtained the same satisfactory results.

A good X-ray equipment performance is not only a matter of complying with the regulations, but also, and more importantly, a matter of permanent interest in improving the quality and efficiency at the radiology centers. Therefore the implementation of quality assurance programs at the institutions operating diagnostic X-ray apparatuses is proposed, with periodical evaluation and adjustment of the equipment by qualified professionals, with the purpose of producing high quality images to allow correct diagnoses, with a reduction of the radiation dose delivered to patients and involved professionals exposed to radiation, as well as reducing the costs for the centers, as a result of the reduction of imaging studies repetitions.

Acknowledgements

The authors wish to thank the team of the Agevisa-PB Technical Board of Directors of Medical Science and Technology and Correlates for the support in the development of the present study.

REFERENCES

1. Furquim TAC, Costa PR. Garantia de qualidade em radiologia diagnóstica. Rev Bras Fis Med. 2009;3:91-9.

2. Organización Panamericana de la Salud. Garantía de la calidad en radiodiagnóstico. México: OPS; 1984.

3. Secretaria de Estado da Saúde. Norma técnica que dispõe sobre o uso, posse e armazenamento de fontes de radiação ionizante, no âmbito do Estado de São Paulo. Resolução SS 625/94. São Paulo, SP: Diário Oficial do Estado; 14/12/1994.

4. Moores BM, Watkinson AS, Henshaw ET, et al. Quality control in diagnostic radiology. In: Oberhofer M, editor. Advances in radiation protection. 1st ed. Brussels and Luxembourg: Kluwer Academic Publishers; 1991. p. 209-36.

5. Yacovenco A, Lira SH, Borges JC, et al. Programa de garantia de qualidade em radiologia diagnóstica. RBE/CEB. 1994;10:7-19.

6. Brasil. Ministério da Saúde. Secretaria de Vigilância Sanitária. Diretrizes de proteção radiológica em radiodiagnóstico médico e odontológico. Portaria nº 453. Brasília, DF: Diário Oficial da União; 2/6/1998.

7. Ros RA. Metodologia de controle de qualidade de equipamentos de raios X (nível diagnóstico) utilizados em calibração de instrumentos [dissertação]. São Paulo, SP: IPEN/USP; 2000.

8. Netto TG. Garantia e controle de qualidade em radiodiagnóstico. [acessado em 17 de fevereiro de 2010]. Disponível em: http://www.rxnet.com.br/fique_informado/documentos/controle_%20qualidade.pdf

9. Pereira MG. Métodos empregados em epidemiologia. In: Pereira MG. Epidemiologia: teoria e prática. Rio de Janeiro, RJ: Guanabara Koogan; 1995. p. 269-88.

10. Protocolo de avaliação de proteção radiológica em radiodiagnóstico médico. Rio de Janeiro, RJ: RXD-URMCF, IRD/CNEN; 2000.

11. Brasil. Ministério da Saúde. Agência Nacional de Vigilância Sanitária. Radiodiagnóstico médico: desempenho de equipamentos e segurança. Brasília, DF: Editora Anvisa; 2005.

12. Medeiros RB, Alves FFR. Análise dos resultados do programa de gerenciamento da qualidade dos equipamentos radiológicos. Rev Imagem. 1997;19:97-9.

13. Silva MO, Carvalho ACP, Azevedo ACP. Levantamento das condições de funcionamento dos serviços de radiologia de hospitais públicos e universitários do Rio de Janeiro. Radiol Bras. 2004;37:271-8.

14. Carrizales LI, Cozman A. Quality control in radiodiagnosis in Venezuela, 1989-1990. Phys Med. 1990;6:255-7.

15. Bacelar A, Oliveira SS, Streck EE, et al. Avaliação preliminar de parâmetros operacionais em equipamentos fixos de raios X diagnóstico. Radiol Bras. 1998;31:129-33.

16. Gori C, Belli G, Calvagno S, et al. Quality control in the radiological departments of the Florence General Hospital. Radiat Prot Dosimetry. 1995;57:315-6.

1. Master of Preventive and Child Dentistry, Health Surveyor, Agência Estadual de Vigilância Sanitária da Paraíba (Agevisa-PB), João Pessoa, PB, Brazil.

2. Specialist in Pediatric Dentistry, Health Surveyor, Agência Estadual de Vigilância Sanitária da Paraíba (Agevisa-PB), João Pessoa, PB, Brazil.

3. Master of Urban Engineering, Health Surveyor, Agência Estadual de Vigilância Sanitária da Paraíba (Agevisa-PB), João Pessoa, PB, Brazil.

Mailing Address:

Adriana Carla Rodrigues Mendes

Rua Lindolfo José Correia das Neves, 419, ap. 502, Jardim Oceania

João Pessoa, PB, Brazil, 58037-305

E-mail: mendesadriana1@hotmail.com

Received October 20, 2010.

Accepted after revision June 29, 2011.

Study developed at Agência Estadual de Vigilância Sanitária da Paraíba (Agevisa-PB), João Pessoa, PB, Brazil.